Why Industrial Water Pumps Are Critical for Modern Large-Scale Irrigation

Rising Water Demand in Commercial Agriculture and Infrastructure Gaps

Farming takes up around 70 percent of all the fresh water we have on the planet, but our old water transport systems just aren't keeping up anymore. These outdated infrastructures leave big holes in how efficiently we move water around, especially when dealing with big farms. Climate changes are getting worse year after year, and farmers need more land to grow crops too. That's where industrial water pumps come into play. They help get water from places like rivers and underground reservoirs out to the fields where it's needed most. The problem is that many of these older systems leak water everywhere and lose even more to evaporation, which means less water actually reaches the crops. Newer pumps can fix this issue by moving exact amounts of water through huge irrigation setups. Farmers in remote areas benefit because they finally get better access to water without wasting as much. Studies show modern systems cut down on water waste somewhere between 15 and maybe 30 percent compared to what was used before. Getting this kind of efficiency matters a lot if we want to keep feeding people as fresh water becomes harder and harder to find.

How System Head and Flow Rate Define Industrial Water Pump Performance

When looking at industrial water pumps, two main factors determine their effectiveness: flow rate (usually measured in gallons per minute or cubic meters per hour) and system head (typically given in feet or meters of pressure). The flow rate basically tells us how much water actually gets moved through those irrigation channels. System head measures what kind of energy push we need to get water past hills and through pipes that create drag. Getting these numbers right matters a lot. If the pump is too small, crops won't get enough water. But going too big just burns extra electricity and wears out parts faster. Take centrifugal pumps for example. These machines need pretty exact matching between head and flow rates. Even a small 10% error here can mean using 25% more power than necessary. Good systems calculate something called Total Dynamic Head (TDH), which combines all the vertical lifting needed plus pipe resistance factors. This helps maintain steady performance no matter what the landscape throws at it. Variable frequency drives (VFDs) take things even further by tweaking pump output based on actual needs at any given moment. This prevents wasting resources when demand drops off during certain times of day or season.

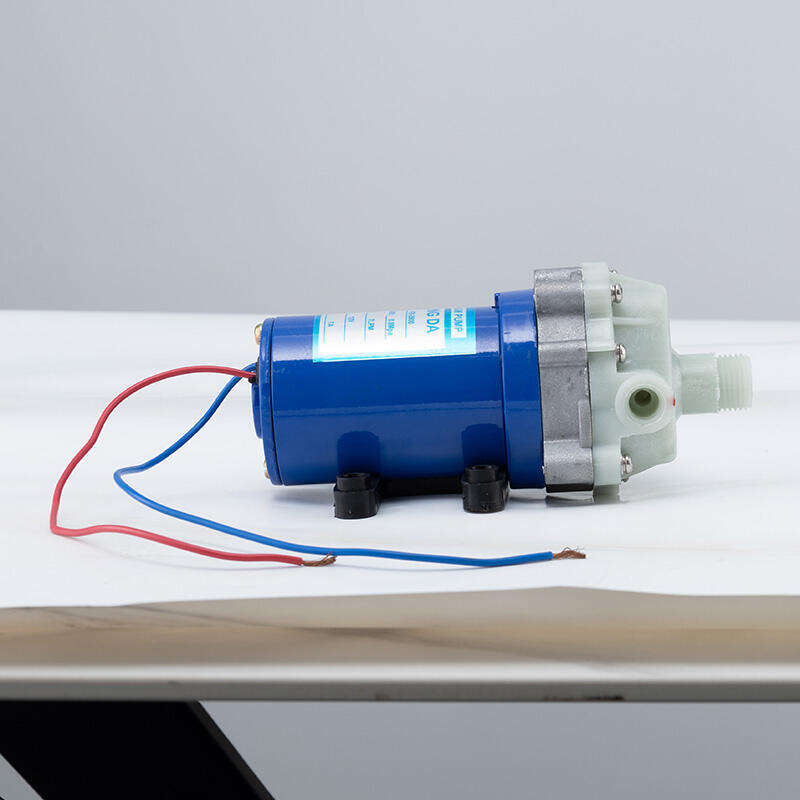

Top Industrial Water Pump Types for Farm Water Transfer

Centrifugal Pumps: High-Flow Efficiency for Surface Water Systems

Centrifugal pumps are the go to choice for most surface water irrigation setups. These pumps work by spinning impellers that basically push water along through kinetic energy transfer. The flow rate typically ranges between 50 gallons per minute all the way up to over 500 GPM, which makes them perfect for those big center pivot systems and standard sprinklers that pull water from nearby ponds, rivers, or reservoirs. They tend to run best when dealing with clean water sources and situations where the pump needs to lift water less than 100 feet vertically. Plus, compared to some fancy specialty pumps out there, centrifugals usually cost less initially and don't need as much maintenance. But there's a catch though - these pumps absolutely need to be primed before starting, and they struggle mightily with water containing lots of sediment or when trying to draw water from really deep wells because of their limited suction power. For big farms that need to move massive volumes of water across flat fields, the ease of installation combined with decent energy efficiency still makes centrifugal pumps the top pick among surface pumping solutions despite their limitations.

Vertical Turbine and Submersible Pumps: Reliable Deep-Well and Low-NPSH Solutions

When dealing with deep water extraction problems that standard centrifugal pumps can't handle because of Net Positive Suction Head limitations, vertical turbine and submersible pumps come to the rescue. Submersible models work best when completely underwater, actually pushing water instead of trying to pull it up against gravity. They're particularly good for wells going down past 100 feet deep while taking up very little space above ground. Vertical turbines have those multi stage impellers mounted along long shafts making them ideal for deep sumps or boreholes. Both pump types stand head and shoulders above centrifugal models when it comes to handling gritty, dirty water and keeping pressure steady even when flow rates change throughout the day. The sealed construction helps prevent cavitation issues in areas with poor suction head conditions, which means these systems stay running reliably at around 85% efficiency rates even out in isolated farming communities. Farmers who rely on groundwater sources or need access to deep reservoirs find these durable pumping solutions essential for maintaining water supply during drought periods when other equipment might fail.

Power Source Selection for Industrial Water Pumps on Remote Farms

Electric, Diesel, and Solar/Hybrid Options: Trade-offs in Reliability, Cost, and Scalability

Selecting the optimal power source for industrial water pumps in remote agricultural operations requires balancing reliability, lifetime cost, and scalability. Each option presents distinct trade-offs:

- Electric pumps offer low operating costs and minimal maintenance where grid access exists–but rural power instability risks irrigation interruptions.

- Diesel-powered units provide high reliability independent of electrical infrastructure, though fuel and maintenance expenses run 30–40% higher than electric alternatives, per agricultural energy studies.

- Solar/hybrid systems eliminate fuel costs and support modular expansion via added panels or batteries, though initial investment exceeds other options. Because cloud cover limits generation, battery backup is essential for uninterrupted operation during low-sunlight periods.

Farmers must weigh site-specific factors–including sunlight exposure, fuel transport logistics, and grid resilience–to prioritize either upfront affordability (electric), operational independence (diesel), or long-term sustainability (solar/hybrid). Hybrid configurations pairing solar with diesel backup are increasingly adopted as balanced solutions for grid-isolated farmlands.

Key Selection Criteria for Industrial Water Pumps in Agriculture

Beyond Flow and Head: Water Quality, Maintenance Access, and Total Cost of Ownership

When picking out pumps for farm work, flow rate and head pressure are definitely important basics, but there are actually three other factors farmers tend to forget about. The water itself plays a big role in how long equipment lasts. If the water has salt in it or lots of dirt particles, regular pumps will wear out much faster than they should. That's why stainless steel parts make all the difference in these situations. Getting maintenance done is another major concern, especially where farms are far from town. Pumps that come apart easily and have nearby repair services mean less time sitting idle when harvest season hits. And here's something most people overlook completely: look at what the pump will cost over its whole life, not just what it costs upfront. Electricity alone eats up around half of everything spent on a pump throughout its lifespan, so efficiency really matters. For places without reliable power lines running through them, going with solar powered options might seem expensive at first glance. But wait till those bills start coming in year after year. Farmers who switch to these hybrid systems save about 30% on overall costs within ten years because they're not paying for diesel or electricity anymore.

Frequently Asked Questions

Why are industrial water pumps important for agriculture?

Industrial water pumps are vital for agriculture as they efficiently transport water from sources to fields, addressing infrastructure gaps and reducing waste through evaporation and leakage.

What factors determine industrial water pump performance?

Two main factors, flow rate and system head, determine pump performance. Proper calibration ensures efficient water movement and energy use.

What are the top types of industrial water pumps for farms?

Common types include centrifugal pumps for surface water and vertical turbine/submersible pumps for deep wells, chosen based on specific needs.

How do farmers choose the best power source for pumps?

Farmers select power sources–electric, diesel, solar/hybrid–based on reliability, cost, scalability, and site-specific factors like sunlight and fuel logistics.

What additional factors should farmers consider when selecting pumps?

Water quality, maintenance ease, and the pump's total cost of ownership are crucial aspects that affect longevity and long-term expense.

Table of Contents

- Why Industrial Water Pumps Are Critical for Modern Large-Scale Irrigation

- Top Industrial Water Pump Types for Farm Water Transfer

- Power Source Selection for Industrial Water Pumps on Remote Farms

- Key Selection Criteria for Industrial Water Pumps in Agriculture

-

Frequently Asked Questions

- Why are industrial water pumps important for agriculture?

- What factors determine industrial water pump performance?

- What are the top types of industrial water pumps for farms?

- How do farmers choose the best power source for pumps?

- What additional factors should farmers consider when selecting pumps?