Why Adblue Pumps Are Essential for Modern Diesel Fleet Compliance

For diesel fleets trying to stay compliant with tough regulations such as Euro 6 standards or EPA Tier 4 requirements, Adblue pumps play a really important role. The system works by injecting DEF fluid into SCR units where it transforms dangerous NOx gases into just plain old nitrogen and water vapor. Get the dosage wrong even by a small margin, usually around 2%, and suddenly those SCR systems become much less effective. That kind of drop in performance can lead to serious compliance issues down the road for fleet operators who need to maintain their environmental credentials while keeping operations running smoothly.

Fleet operators face severe penalties for violations, including fines up to $740k per incident, and operational shutdowns. Modern Adblue pumps prevent this by:

- Ensuring consistent DEF flow rates (5–25 liters/minute)

- Maintaining optimal pressure (5–9 bar)

- Resisting urea crystallization with HDPE or stainless steel components

Beyond compliance, properly functioning pumps reduce downtime by 30% and extend SCR catalyst lifespan. Failure rates spike by 60% when using non-certified systems, underscoring the need for ISO 22241-1 adherence. Ultimately, investing in robust Adblue infrastructure safeguards both regulatory standing and operational continuity.

Key Types of Adblue Pumps and Their Operational Differences

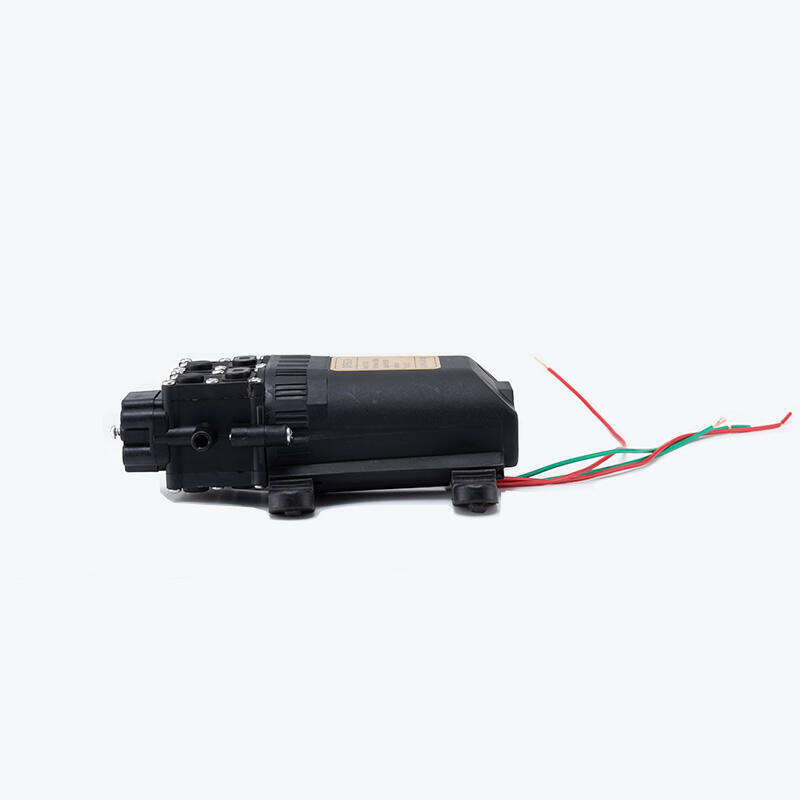

When it comes to picking out an Adblue pump, there are basically three main types to consider. The old fashioned hand operated ones work fine for small jobs or when something breaks down unexpectedly, though they do mean spending extra time on pumping instead of other tasks. Electric models handle moderate amounts better, giving operators more control over how much gets dispensed at once which makes them great for regular maintenance schedules. Then we have those fancy automatic systems that hook into fleet management programs. These smart setups adjust the dosage according to what the SCR system actually needs at any given moment. Some studies suggest this can cut down on overall Adblue usage somewhere around 15 percent versus just guessing with manual pumps.

Manual, Electric, and Automatic Adblue Pumps

- Manual Pumps: Require physical operation, risking spillage and inconsistent dosing. Best for backup use or small fleets with infrequent Adblue needs.

- Electric Pumps: Use motors for precise transfer, maintaining ISO 22241-1 fluid purity standards. They handle ~20–60 liters per minute (LPM), fitting mid-sized depots.

- Automatic Pumps: Enable hands-free operation via sensors and IoT connectivity. Self-calibrate for ±0.5% accuracy, preventing over/under-dosing that can trigger €10k+ regulatory fines.

Flow Rate, Pressure, and Dispensing Accuracy Specifications

Critical performance metrics vary by pump type:

| Pump Type | Flow Rate (LPM) | Operating Pressure (psi) | Accuracy | Best Use Case |

|---|---|---|---|---|

| Manual | 5–15 | 10–20 | ±2% | Emergency/temporary stations |

| Electric | 20–60 | 30–50 | ±1% | Daily fleet refueling |

| Automatic | 40–100 | 50–100 | ±0.5% | High-volume terminals with SCR |

Higher-pressure systems (e.g., automatic pumps) prevent crystallization in lines, while flow rates above 60 LPM cut refill time by 40% for Class 8 trucks. Accuracy below ±1% is essential to avoid NOx emissions exceeding 0.4g/kWh under Euro 6 standards.

Critical Selection Criteria for Reliable Adblue Pump Performance

Material Compatibility and Corrosion Resistance (e.g., HDPE, Stainless Steel)

What materials go into building an Adblue pump has a huge impact on how long it lasts and whether it stays safe during operation. The urea in AdBlue at around 32.5% concentration eats away at certain metals pretty quickly, so using materials that can stand up to chemicals becomes absolutely essential. Most good quality pumps use HDPE for their housing because this stuff just doesn't break down when exposed to AdBlue. For internal parts, many manufacturers opt for AISI 316L stainless steel since it handles those nasty corrosive effects much better than regular steel grades. Top tier suppliers don't just claim their materials work well they actually put them through rigorous testing including 5,000 hours of salt spray exposure and repeated cycles in simulated harsh conditions found at fuel depots. These tests help confirm that the pumps won't leak or lose performance over time even after years of constant use in tough environments.

Certifications, CE/ATEX Compliance, and ISO 22241-1 Adherence

Getting the right regulatory certifications helps fleet operators avoid all sorts of headaches down the road, both operationally and legally speaking. The CE mark basically tells everyone that equipment meets EU safety standards, whereas ATEX compliance under Directive 2014/34/EU becomes non-negotiable when dealing with pumps in potentially explosive environments. What really matters though is ISO 22241-1 certification since it ensures pumps work properly with AdBlue's exacting purity specs. Without this, there's a real risk of damaging those expensive catalytic converters through contamination issues. Manufacturers who undergo third-party audits show they can maintain around 99.98% fluid purity levels throughout their systems. This makes sense because fleets report roughly 74% fewer SCR system problems when using certified pumps versus ones that haven't gone through proper certification processes.

Installation, Maintenance, and Troubleshooting Best Practices

Safe Integration with Bulk Storage Tanks and Dispensing Infrastructure

Getting Adblue pumps installed right means making sure they connect properly to those big storage tanks and the dispensing system so nothing leaks out or gets contaminated. The connections need to match what the manufacturer says, and stainless steel fittings work best since they stand up better against corrosion from the urea stuff. Before turning anything on, check that grounding is solid and pressure ratings are correct. Improper alignment actually leads to about a third of all component failures when moving chemicals around, which nobody wants. Leave at least 18 inches free space around the equipment for proper airflow and easy maintenance access. Also important is setting up some kind of secondary containment area just in case there's ever a spill situation.

Preventive Maintenance Schedules and Common Failure Signs

Quarterly preventive maintenance should be scheduled for Adblue pumps, covering things like checking the diaphragms, replacing worn seals, and making sure nozzles are properly calibrated. Watch out for signs something might be wrong - if flow drops below 8 liters per minute, there's visible crystallization forming around connections, or pressure readings start acting strange, these are red flags. Keep detailed records of all maintenance work through a standard checklist so we can monitor how long components actually last in practice. Most diaphragms tend to need changing somewhere between 12 to 18 months when everything runs normally. Don't ignore those error messages either. Codes such as E7 which means motor overload or F2 indicating pressure loss must be dealt with right away before they cause serious damage to the SCR system down the line.

Cost Efficiency and ROI: How the Right Adblue Pump Reduces Long-Term Operational Costs

Getting the right Adblue pump can save money in ways that go way beyond just the price tag at checkout. Sure, those cheap models look tempting when looking at the bottom line, but they tend to break down more often and need constant attention which ends up costing much more over time. The better quality pumps made from stuff that won't corrode easily, think HDPE or stainless steel, last around three times longer than cheaper alternatives before needing replacement. And let's not forget about energy efficiency either. Pumps equipped with variable frequency drives actually use about a quarter less power while dispensing, which adds up nicely on monthly utility bills for facilities running these systems regularly.

The most significant savings come from preventing operational disruptions. Fleet downtime due to Adblue system failures costs commercial operators approximately $740/hour. Pumps with predictive maintenance capabilities and remote monitoring slash unplanned outages by detecting issues like seal degradation or pressure fluctuations early. When evaluating options, consider:

| Cost Factor | Low-Quality Pump | Premium Pump |

|---|---|---|

| Annual Maintenance | 3–5 service interventions | 1–2 interventions |

| MTBF* | ≤ 8,000 hours | ≥ 15,000 hours |

| Energy Consumption | 15–20% higher | Optimized flow efficiency |

| Failure Downtime | 20+ hours/year | <5 hours/year |

This reliability-focused approach typically delivers 12–18 month ROI through reduced service calls, lower energy bills, and sustained fleet compliance. Premium Adblue pumps ultimately minimize environmental penalties while maximizing uptime—critical for cost-sensitive logistics operations.

*Mean Time Between Failures

Frequently Asked Questions

What is Adblue?

Adblue is a liquid solution made from urea and deionized water used to reduce emissions from diesel engines. It converts harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor.

Why is Adblue important for diesel fleets?

Adblue is crucial for diesel fleets as it helps in reducing emissions to meet regulatory standards like Euro 6 and EPA Tier 4, thereby avoiding penalties and operational shutdowns.

How do Adblue pumps improve compliance?

Adblue pumps ensure the correct dosage of DEF fluid is injected into SCR units, maintaining efficiency in transforming NOx gases, which is vital for compliance with environmental regulations.

What are the types of Adblue pumps available?

The main types of Adblue pumps are manual, electric, and automatic, each offering different benefits in terms of dosing accuracy, flow rate, and ease of operation.

What materials are used in high-quality Adblue pumps?

High-quality Adblue pumps typically use HDPE for housing and AISI 316L stainless steel for internal components due to their resistance to chemical corrosion.

How often should Adblue pumps be maintained?

Adblue pumps should undergo preventive maintenance quarterly, including checks and calibrations to ensure long-term operational efficiency.

Table of Contents

- Why Adblue Pumps Are Essential for Modern Diesel Fleet Compliance

- Key Types of Adblue Pumps and Their Operational Differences

- Critical Selection Criteria for Reliable Adblue Pump Performance

- Installation, Maintenance, and Troubleshooting Best Practices

- Cost Efficiency and ROI: How the Right Adblue Pump Reduces Long-Term Operational Costs

- Frequently Asked Questions