The Shift to Electric Power in Agricultural Spraying

How electric power is transforming traditional spraying methods

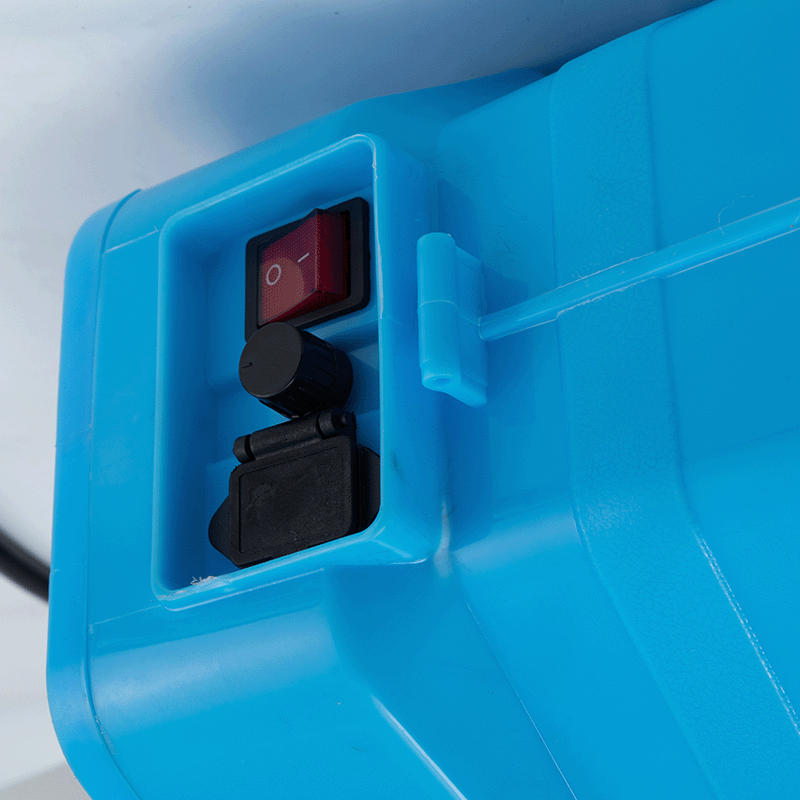

Switching from old school gas powered gear to these new electric sprayer setups marks a pretty big deal in farming tech these days. Gas engines need constant refills and spew out all sorts of harmful emissions, while batteries keep going strong without any exhaust fumes at all. Farmers can work longer hours without worrying about running out of fuel, plus there's hardly any damage done to the environment. Another nice thing about electric sprayers? They don't vibrate as much and they're way quieter than their noisy counterparts. This makes a world of difference when someone has to spend hours spraying crops across vast stretches of land. Plus, these machines come with built in smart features that let farmers tweak the pressure and flow exactly how they want it. Less wasted chemicals means better money management for big operations dealing with pests on a massive scale.

Comparative energy efficiency: electric vs. gasoline-powered sprayers

When it comes to getting the most bang for their buck, electric sprayers beat out gas-powered ones hands down when looking at energy efficiency. These electric models actually convert around 85% of their battery power into actual work, while those old fashioned gas engines only manage about 25 to 30%. And let's talk money too. Running costs drop dramatically with electric options. Farmers report spending roughly 30 cents on electricity per acre sprayed, whereas gas sprayers can burn through anywhere from $2.50 to $3 dollars covering both fuel and all those inevitable repairs (as noted in the USDA Energy Efficiency Report from last year). Just wait till you see the numbers laid out in the table coming up next.

| Performance Metric | Electric Sprayers | Gasoline Sprayers |

|---|---|---|

| Energy Efficiency | 85-90% | 25-30% |

| Operating Cost/Acre | $0.30 | $2.50-$3.00 |

| Noise Level | 65-70 dB | 85-95 dB |

| CO2 Emissions | 0 g/h | 2,500-3,000 g/h |

These advantages are especially impactful for farms managing hundreds or thousands of acres annually.

Adoption trends in North America and Europe

Farmers across North America and Europe are jumping on board with electric spraying tech at an incredible pace. The numbers tell the story best really - market growth for these systems shot up 200% from 2020 to 2023 according to those agricultural tech adoption reports we keep hearing about. Over in the EU, governments pushing for lower carbon footprints has definitely sped things along. Look at Germany and France specifically where nearly a third of medium to large farms already run their operations with electric sprayers. Things aren't slowing down across the pond either. Take California's Central Valley region for example, where almost 28% of growers have made the switch primarily because they need to meet strict state emissions rules but also because running costs just make too much sense to ignore. What we're seeing here is part of something bigger happening throughout agriculture right now. Sustainability isn't just buzzword anymore; it's becoming practical reality as farmers balance planet friendly practices with bottom line concerns.

Electric Sprayers and Sustainable Farming Practices

Reducing carbon emissions with battery-powered sprayer systems

Electric sprayer systems that run on batteries don't release any greenhouse gases while working in the fields. Gasoline versions are another story altogether they put out about 4.7 kilograms of CO2 for every gallon burned according to some USDA numbers from last year. Switching over to electric means no exhaust fumes at all. Many farms have made the switch and seen their carbon footprints drop by as much as 89 percent, particularly those using solar or wind power to charge their equipment. Getting rid of fossil fuels also cuts down on accidents where fuel might spill into soil or water during refills, which makes operations cleaner overall and shows better care for the environment.

Integration with renewable energy sources on farms

Electric sprayers work really well with renewable energy systems already set up on many farms, creating more sustainable ways to manage pests. Farmers who install solar charging stations find their sprayer batteries get a full charge within about 2 to 4 hours from those big solar panels. The sun that hits these panels during daylight hours ends up powering important crop protection tasks later in the day or night. Some recent research looking at farm energy usage shows that when solar power meets electric spraying tech, carbon emissions drop by around 95% compared to old school methods. What makes this setup so good is it cuts down on needing electricity from outside sources while also protecting farmers against wild swings in fossil fuel prices. Over time, this means cleaner air for everyone and better control over farming costs without relying so much on unpredictable market forces.

Spray Efficiency and Coverage Performance of Electric Sprayers

Uniform droplet distribution and canopy penetration data from field trials

Tests in real fields indicate electric sprayers spread droplets much more evenly than regular spraying equipment does. The electrostatic charge technology gets around 95 percent coverage on leaves both above and below because it creates tiny charged particles that stick better to plants. Farmers have noticed this approach cuts down on spray drifting away from target areas by about seventy percent, plus it penetrates through thick crop canopies where traditional methods often fail. Better still, pesticides work their intended effects more effectively when they actually reach the pests instead of floating offsite. For big operations dealing with widespread infestations, these electric models seem to offer real advantages over older technologies despite their higher initial costs.

Impact of adjustable pressure systems on spray efficiency

Electric sprayers these days come equipped with digital pressure controls that keep the spray going steady even when batteries start running low. The system knows what to do as the operator moves faster or slower over fields, so the amount sprayed stays pretty much the same no matter what kind of ground they're working on. Farmers can actually change how big those tiny drops are from around 150 all the way up to 500 microns, which makes a real difference depending on what crop is growing and where it stands in its life cycle. And here's something interesting: tests show these modern machines waste about 40 percent fewer chemicals than older mechanical versions, yet still get most of the stuff exactly where it needs to go on plants.

Case study: 30% reduction in chemical usage on a 500-hectare wheat farm

On a 500 hectare wheat farm in Saskatchewan, farmers noticed something interesting when they switched to electric sprayers last season. Chemical usage dropped around 30%, yet pests stayed under control just as effectively as before. Fuel expenses went down nearly half, saving thousands each year, while getting rid of about 12 tons worth of carbon dioxide emissions annually. The real magic happened because these machines could target specific areas needing treatment instead of blanket spraying everything. Less runoff means cleaner waterways nearby. Looking at this example shows why many big farms are now considering electric sprayers not just for their bottom line but also for planet health reasons.

Advanced Features Enhancing Pest Control Efficiency

Smart nozzles and automated boom calibration systems

Modern electric sprayers feature smart nozzles that change flow rates depending on how fast the machine is moving and what kind of terrain it's covering. This helps keep chemicals applied evenly across fields. When combined with automatic boom calibration technology, these sprayers can hold the right height and angle throughout operations. Farmers report less drift issues and better coverage when they switch from old school methods. According to research done in actual farming situations, most operations see around 95% uniformity in their spraying patterns with these new systems. That's way better than the 70 to 80% range seen with traditional equipment. The difference means fewer chemicals end up wasted or harming unintended areas, yet pests still get properly controlled without compromising crop health.

Real-time monitoring of pest infestation and targeted spraying

Modern electric sprayers come equipped with sensors and cameras that spot pests and stressed plants as they move through the fields. This means farmers can spray pesticides right where they're needed instead of dousing entire areas, cutting chemical use down somewhere around 40 to maybe even 60 percent compared to old school methods. The smart tech inside these machines reacts fast when conditions change on the ground. Some advanced models actually tell the difference between various weeds and different kinds of insect damage, letting them adjust their approach on the fly for much better results.

Data from USDA: 25% faster application rates compared to manual methods

USDA figures from 2023 indicate that electric sprayer systems can cover ground about 25 percent quicker than old fashioned manual approaches, plus they tend to be much more accurate when it comes to spreading stuff evenly. Why? Because these machines have built in controls that adjust how the spray gets distributed across fields, which cuts down on mistakes people might make when setting things up themselves. Looking at those same numbers again, we find that farms equipped with modern electric sprayers see around 30% less need for going back over areas that weren't properly treated initially. They also waste significantly less chemicals overall, cutting usage by nearly half compared to conventional methods. These reductions translate directly into real money saved for farmers while making their operations better for the environment too, especially important for big agricultural businesses trying to balance profits with sustainability concerns.

Electric Sprayer Types and Applications in Large-Scale Agriculture

Backpack, boom, and aerial sprayers: A functional comparison

Farms today generally use three main kinds of electric sprayers depending on their size and what kind of land they need to cover. For smaller areas or when farmers just need to treat specific spots, backpack sprayers are the go-to choice. These portable units come with built-in batteries so there's no need to manually pump them, which means steady pressure even when moving around fields all day long. When dealing with big fields of row crops though, boom sprayers take center stage. They can spread chemicals across widths over 30 meters wide and handle anywhere from 50 to 80 hectares per day thanks to GPS guidance systems that make everything run smoother. And then there are those tricky areas where regular equipment struggles. That's where aerial sprayers shine, especially drones equipped with advanced tech. These flying machines can reach places that are either too wet or otherwise hard to access, applying treatments with pinpoint accuracy down to the centimeter level. According to recent research in precision agriculture (as of 2024), this approach cuts down on chemical drift by about half compared to older aerial spraying techniques.

Why electric models outperform in mid-to-large scale row crops

Electric sprayers are becoming increasingly popular among farmers working medium to large farms because they save energy and offer better control. Compared to those old gas powered machines, these electric versions maintain consistent pressure without all those annoying torque changes that mess with droplet sizes during spraying. The result? Farmers can actually cut down on chemicals by about 20 to maybe even 30 percent, which is pretty impressive when looking at fields of thick crops such as corn or soybean plantations where getting good coverage matters most. What really stands out though is how quickly these sprayers respond to different conditions across the field. They adjust the spray amount automatically depending on what the sensors detect about plant density and where exactly the tractor is positioned within the field boundaries. This means less waste and better results overall for anyone serious about efficient farming practices.

Hybrid electric-tractor integration for continuous operation

The hybrid electric tractor system solves the problem of limited runtime that comes with purely battery powered sprayers. These systems tap into the tractor's own power generation capabilities to drive those big electric pumps we need for serious spraying jobs. What does this mean in practice? Farmers can keep working straight through their entire shift without stopping to swap batteries every few hours. Most setups will last between twelve and sixteen hours nonstop, which makes all the difference when covering large fields. Recent studies from the 2024 farming efficiency reports show something pretty impressive too – these hybrids cut down on fuel use anywhere from forty to sixty percent compared to old fashioned PTO driven sprayers. Plus there's another bonus: the modular nature of these systems means farmers don't have to throw away their current equipment just to get the benefits of electric tech. They can keep using what they already own while slowly transitioning to newer electric application methods over time.

Trend: Shift toward autonomous electric sprayer fleets

More and more farms around the world are starting to roll out their own electric sprayer teams, blending electricity with smart automation technology. These sprayers work together using sophisticated coordination methods, covering large areas of farmland at once. Farmers report getting their spraying done about a quarter quicker compared to old fashioned manual work, plus these machines can hit targets within just an inch or so. With constant data exchange between units and GPS guidance built right in, these systems keep running day and night when timing matters most for crops. Looking at worldwide numbers, we've seen something pretty remarkable happen since 2022. The use of these autonomous spraying setups has shot up by three times what it was before. Labor problems on farms and the need for better precision have pushed this trend forward fast, as growers look for ways to scale up operations while still keeping costs under control.

Frequently Asked Questions

What are the advantages of electric sprayers over gasoline-powered ones?

Electric sprayers offer several advantages over gasoline-powered ones, including higher energy efficiency, reduced operating costs, lower noise levels, and zero CO2 emissions.

How do electric sprayers integrate with renewable energy sources?

Electric sprayers can be charged using renewable energy sources like solar panels, which helps in reducing carbon emissions and minimizing dependency on external electricity sources.

What types of electric sprayers are available for farming?

The main types of electric sprayers used in agriculture are backpack sprayers, boom sprayers, and aerial sprayers such as drones. Each serves different purposes based on the scale and nature of the farming land.

What impact do electric sprayers have on chemical usage and pest control?

Electric sprayers allow for more precise targeting and uniform droplet distribution, leading to reduced chemical usage while maintaining effective pest control. They can lower chemical drift and enhance canopy penetration.

How are electric sprayers contributing to sustainable farming practices?

Electric sprayers contribute to sustainable farming practices by eliminating greenhouse gas emissions, reducing chemical runoff, integrating with renewable energy, and enhancing precision in pesticide application.

Table of Contents

- The Shift to Electric Power in Agricultural Spraying

- Electric Sprayers and Sustainable Farming Practices

- Spray Efficiency and Coverage Performance of Electric Sprayers

- Advanced Features Enhancing Pest Control Efficiency

- Electric Sprayer Types and Applications in Large-Scale Agriculture

-

Frequently Asked Questions

- What are the advantages of electric sprayers over gasoline-powered ones?

- How do electric sprayers integrate with renewable energy sources?

- What types of electric sprayers are available for farming?

- What impact do electric sprayers have on chemical usage and pest control?

- How are electric sprayers contributing to sustainable farming practices?