Cur Pumpae Pumpae in Industriis Omnibus Necessariae Sint

Pumps magnam partem in cotidianis operis industrialis locis gerunt, liquidos certe et accurate movebant per industrias a petrolio et gaso ad manufacturam medicamenti, lineas cibariae, et loca agraria. Secundum recentia data e Rapporto Industriali Globales edito anno superiore, circiter tres quartae partes omnium fabricarum in systematis pumparum confidunt cotidie tantum ut operationes suas sine interruptione peragant. Quae hos machinas tam pretiosas reddit est eorum facultas cum prope omni genere liquidi operari - cogita qua ratione mineras asperas misturas unico momento et lactes delicates proximo sine ulla interruptione regant. Pro agricolis qui cum restricto aquae aditu pugnant, pumps iuvant duos tertios agrorum rigare. Interim centra tractationis sordidarum aquarum etiam in eis confidunt, tractando prope 1,2 miliardorum galonum valorem sordidarum aquarum cotidie per totam terram.

Principia Liquidae Transferendi in Operationibus Industrialibus

Translatio liquida efficax nititur tribus principiis fundamentalibus:

- Control praesentis : Retinendo vim sufficientem ad resistendum viarum resistentiae et mutationibus altitudinis

- Constantia Taxonis Fluminis : Certificando constantem distributionem, quae in processibus ut in mixtione et dosatione chimica est critica

- Material Compatibility : Seligendo materiales constructionis, ut ferrum inox, ceramica, vel ligas internutritas, secundum proprietates fluidorum sicut corrosivitatem aut abrasi vitam

Pumpae centrifugae praedominantur in applicationibus alti voluminis, capaces moventis usque ad 15,000 GPM, dum pumpae cavitatis progressivae 98% efficientiam praebent cum liquido viscoso ut oleum crude vel limus tractantur.

Applicationes Clavis in Oleo & Gaso, Chemico, et Cibario & Potabili Sectoribus

| Industria | Uti causa | Genus sentinam | Necessitas Principalis |

|---|---|---|---|

| Oleum & Gas | Translatio crude offshore | Multistage submersa | Certificatio explose defensiva |

| Chemicum | Circulatio acidi | Centrifugalis foderatus | Materiae crustae PH-neutrae |

| Cibus & Potus | Lactis tractatio | Lobus sanitarius | normae descripti hygienici 3-A |

In processu hydrocarbonum, viscositas praecisa curat ut expensae conservationis ductorum minuantur 40%. Pro applicationibus cibariis, finitiones superficiei infra 0.8 µm colligationem bacteriorum praeventant, ita ut normae FDA et 3-A de sanitatione serventur.

Quomodo pumpam pumping pumpam ad usum multi-sectorem eligere

Eligere pumpam versatilis pumping pumpae quattuor cruciales factores aestimare oportet:

- Caracteres fluidi : Considera densitatem, abradentiam, et sensibilitatem ad scissionem ut degradatio vel obturatio vitetur

- Ambitus Operationis : Certifica quae idonea sint, ut ATEX pro atmosphaeris explosivis aut IP68 pro immersione

- Efficientia Energiae : Motos cum impulsoribus frequentialiter variabilibus (VFDs) consummationem electricitatis usque ad 35% in oneribus variabilibus minuunt

- Expensae totius vitae : Pompe sine valvis, quae magnis viribus tractantur, eliminationem 87% defectuum ex valvis faciunt, necessitudines ad manutentionem notabiliter minuendo

Constructio modularis cum rotoribus et statoribus intermutabilibus adaptabilitatem trans sectores meliorem efficit—71% factoriarum reconfigurationem celeriorem esse afferunt per talia systemata

Designa pumparum versatilia: omnium generum pompis quaestionibus satisfaciens

Auctio solutionum pumparum multifunctionalium

Industria hodie machinas necessitat quae omnia tractent, a spissis petrochemicis ad acida aggressiva et ad delicatas ciborum substantias, omnia in eadem fabrica. Fabricatores magni machinarum nuper hos versatiles systemates divulgare coeperunt. Veniunt cum fluxu inter 0.5 gal/min et usque ad 500 GPM. Quae est autem temperatura? Hi robusti machinae inter -40 gradus Fahrenheit et ardentem calorem 600 graduum operantur. Praeterea, cum partibus ex ferro non comburendo, componentibus ex ceramica, et cum PTFE internis etiam amicabiles sunt. Quid hoc pro rationibus pecuniariae significat? Societates circa 22 ad 35 percent in expensis machinorum pecuniam conservant, cum omnem copiam pumparum speciales abjiciant. Fluid Handling Quarterly hanc sententiam numeris confirmavit anno 2023.

Design Advantages of Positive Displacement and Peristaltic Pumps

Turbine ad translationem positivam praecisam praebent (±1,5%), ideales ad mensuranda applicationes sicut administrationem chemicae. Turbine peristalticae, cum tubo clauso, pericula contaminis tollunt—necessaria in locis pharmaceuticis et biotechnologicis. Innovations principes continent:

- Proprietates sese-primantes ad altitudinem usque ad 28 pedes attingentes

- Configurationes sine signis quae curas tenuiores 40%

- Operatio bi-direcionalis ad systemata flexibilia disponenda

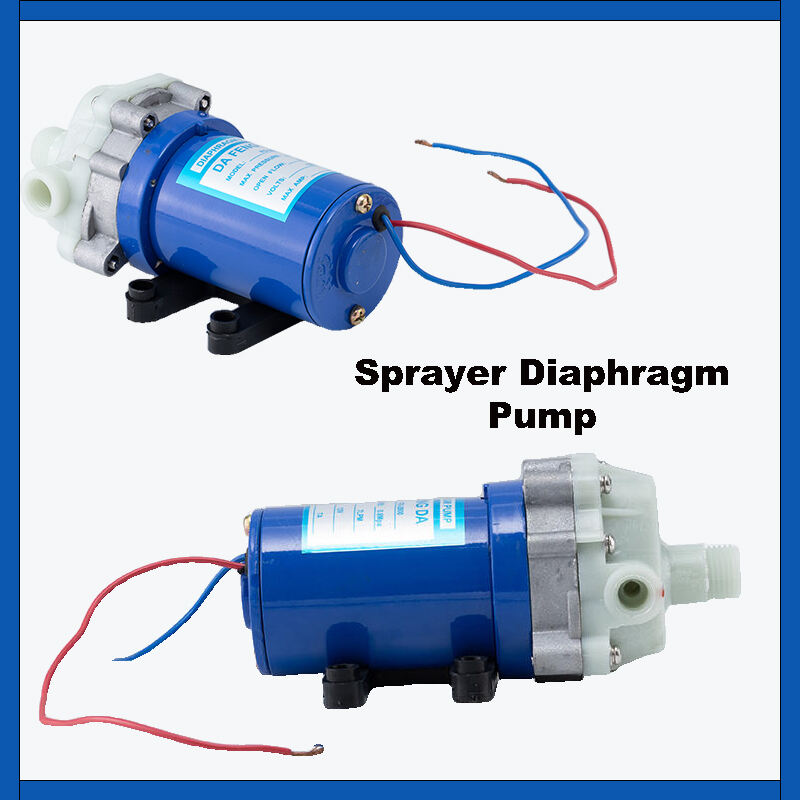

Praestantia realis: Applicatio diaphragmatis, rotae dentatae, et turbine virgae

Studio transversale 2023 secutus est 1200 turbine per 18 menses, praestantias mensas ostendens:

| Genus sentinam | Tempus medium operis | Usus energiae (kW) | Optima Applicatio |

|---|---|---|---|

| Diaphragma | 92% | 7.2 | Translatio limum |

| Apparatus | 88% | 4.8 | Onus carburantis |

| Piston | 95% | 11.4 | Iniectio ad Pressionem Altam |

Conciliatio Versatilitatis et Specializationis in Electione Pumparum

Cum pumpae ad usus multiplices 60–70% necessitatum industrialium implent (Narratio de Mercato Globali Pumparum 2024), applicationes speciales—ut translatio LNG criogenica ad -260°F—adhuc desiderant structuras ad finem fabricatas. Operatori matricem electionis gradatam adhibent ad capacitates pumpae in vinculis viscositatis, magnitudine particulorum, et rationibus Inlocopurificationis (CIP) accomodandas, ut optima functio sine supervacua structura obtineatur.

Economia Energetica et Automatio in Pumpationibus Modernis

Trendi Globales Promotionis Adoptionis Pumpationum Efficientis Energeticis

Systemata pumpandi industrialia circa 25 percentum totius electricitatis in manufactoriis utentium consumunt, quod singulis annis fere duodecim milliaria dolariorum efficit. Hoc igitur cur efficienter haec systemata currere debeant nunc magni momenti est. Quia cum energiae pretiis augentibus et strictioribus legibus ambientalibus quales ISO 50001, societates validiter contendunt ut pumpas suas emendentent. Quod longius tempus spectaturum est etiam monstrat aliquid interessans. Meliores pumpae plerumque sese ipsas citius quam putas solvunt, saepe intra tantum menses duodecim et octo, computatis tum minoribus expensis pro energia, tum paucioribus emendationum expensis futuris.

Quomodo Impulsus Frequentiae Variabiles (VFDs) Efficienciam Pumpandi Meliorem Faciunt

Variatores frequentiae, seu VFDs, faciunt ut res melius currant, quod rotationem motorum variare possunt secundum id quod momento opus est. Comparati cum antiquis pumpis velocitatis constantis, systemata VFDs energiam inter 30 et fortasse usque ad 50 percent minuunt quando non plene operantur. Ratio qua haec opera funtionis valde callida est. Cum minus fluxus opus est, revolutiones per minutum minuuntur potius quam ut pressio augeatur et problemata causentur. Hoc igitur minus laborem in systemate totum inducit et partes diutius durant. Eorum qui in plantis processuum chemicorum operantur, talis subtilis moderatio multum valet. Sic vitatur ut plus producti quam oportet in locis indesideratis ponatur et machinae tardius consumantur. Quaedam aedificia fere septuaginta quinque milia denariorum annis singulis conservare nuntiaverunt propter talia systemata sapientiora.

Pumpae Sapientes: IoT et Automatio in Systematibus Aquae et Sordidarum

Pumps conectos ad Internet of Things habent sensors intrinsecos qui sequuntur res sicut pressionem, mutationes temperaturae et vibrationes. Hoc operarios permittit problemata cito agnoscere et maintenance programmare antequam aliquid penitus interrumpatur. Pro civitatibus quae cum sordida aqua pugnant, hi pumps sapientes vere possunt variare quantitatem aquae quae circum movetur, secundum quid in tubis natat et quantum homines adhibent tempore diei diverso. Quedam loca 22% reductionem in aqua perdita viderunt postquam hi systemata installaverunt. Et cum technici ex longinquo pumporum operationem custodire possunt, problemata circa sigilla vel axiculos multo ante partium defectum agnoscunt, quod significat minus superventaneis durante operationibus criticis.

Strategemata pro Optimizando Functione Pumporum per Automationem

Ad optimas pompas efficiuntur, automationem cum aliis partibus operis coniungere oportet. Primum incipias cum examinationibus energiæ, quæ bene iuvant detegere pompas nimis magnas aut operari nolentes. Postquam hoc perfectum est, instrumenta maintenance prædictiva adhibe ut cingula, tenuitates et sanitatem motorum saepius explorentur. Omnia mutantur, cum systemata SCADA centralia constituuntur, tum enim omnia melius inter se operantur. Cogita quomodo stationes elevationis cum capacitate tractationis disponant, quod adhibetur ad omnis generis reversiones in systemate vitandas. Si omnes hæc rationes combinantur, pleraque opera circa 30-35% meliorationem in tota efficientia conspicuam reddunt, dum multo minus pecunia expenditur ad corrigendum casus inopinati in futuro.

Sustinibilitas et Impactus Ambientalis Pompearum

Aucta Momenti Machinarum Sustentabilium

Leges de conservatione naturae et metas sustentabilitatis corporum mutant machinas pumpantes. Nova systemata crebrius includunt materiae recyclabiles et compatibilitatem cum fontibus energiae renovabilibus. Propter legem 2023 quae iubet operationes industriales carbonii neutras esse ante annum 2035, fabricatores machinas pumpantes tanquam res naturales magis quam partes mechanicas definiunt iterum.

Minuendo Pedes Carbonici Per Machinas Pumpantes Efficientes Energiae

Machinae pumpantes efficientes energiae, praesertim cum VFDs, minuunt consumptionem energiae usque ad 30% comparatis cum machinis velocitatis fixae. Exempli gratia, fabrica lactis energiam suam usum minuit 20% postquam pumpas cum VFDs adaptavit, directe minuens emissionem gazorum serra. Haec emendatio initia net-zero adiuvat dum minuitur damnum durante operatione continua.

Conservatio Aquae in Systematibus Municipalibus Purificationis

Systemata pumpandi sapientia in plantis municipalibus ad purganda aquae vetustae praestant ne effluant et optimant cyclum filtrationis per sensorum retroactionem in tempore reali. Regulando fluxum secundum petitionem et qualitatem aquae, haec systemata minuunt extractionem aquae dulcis usque ad 15% in regionibus ad siccitatem pronis. Haec facultas magni momenti est ad rationabilem urbem aquae gestionem et ad tutandos aquiferos.

Systemata Circuiti Clausi et Rationabilia Fluidorum Gestionis

Operatio refrigerationis industrialis et tractationis chemicis adhibent systemata circuiti clausi cum pumpis redundantis et sensoribus ad detegendas effusiones. Haec recirculationis schemata purificant et reutiuntur fluida processuum, eliminando effluentis rejectionem et minuendo aquae dulcis sumptionem. Minuendo sordes et contaminatio vetando, pumpandi circuiti clausi permittunt fabricandi processus circulares et adiuvant ad leges de medio ambiente servandas.

Frequenter Interrogata (FAQ)

Quae artes et commercia in pumpis pumpandis confidunt?

Pumpae pumpandi sunt necessariae in artibus et commerciis ut olei et gasi, pharmacopoeis, ciborum productione, agricultura et tractatione sordidarum aquarum.

Quae sunt principia principum transferendi liquidi?

Moderatio pressionis, constantia celeritatis fluxus et congruentia materialis sunt principia quae transferentur liquidi in operationibus industrialibus.

Quomodo systemata frequentiae variabiles (VFD) augent efficaciam?

VFD velocitates motorum adaptant secundum necessitates tempus reale, consumptio energiae minuitur 30-50% systematis celeritate fixa et vitae instrumentorum producuntur.

Quomodo systemata pumpae sapientia prosunt plantis municipalibus aquae putridae?

Systemata sapientia sensoribus utuntur ad fluxus regendos, effusionem vitandam, cyclones optime administrandos et extractionem aquae dulcis usque ad 15% in regionibus siccis.

Index Rerum

- Cur Pumpae Pumpae in Industriis Omnibus Necessariae Sint

- Principia Liquidae Transferendi in Operationibus Industrialibus

- Applicationes Clavis in Oleo & Gaso, Chemico, et Cibario & Potabili Sectoribus

- Quomodo pumpam pumping pumpam ad usum multi-sectorem eligere

- Designa pumparum versatilia: omnium generum pompis quaestionibus satisfaciens

- Economia Energetica et Automatio in Pumpationibus Modernis

- Sustinibilitas et Impactus Ambientalis Pompearum

- Frequenter Interrogata (FAQ)